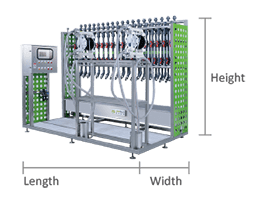

WF-LCRS

Liquid Chemical Refill Station

Feature

- Based on mass flow meters, it can eliminate the disadvantages of inaccurate and unreliable conventional flow meters.

- The special mechanism design enables simultaneous weighing and delivery.

- The structure of the main pipeline and three-way valve simplifies the piping engineering.

- After weighing is completed, the weighing valve and delivery pipeline are automatically cleaned.

- It can be connected to various major central monitoring systems on the market to perform weighing and delivery according to the needs of each dyeing machine.

- With an uninterrupted power supply system, the formula in the weighing process can be maintained during power outages and continued after power is restored.

- Complete weighing material records and daily consumption statistics are helpful for management.

- Integral structure, fast installation, small footprint, and easy external piping.

- Man-machine interface control.

Benefit

Accurate additive weighing and complete delivery, reduce human error, eliminate abnormalities, control the amount of additives, avoid waste, and complete daily statistics

Dyeing smart energy-saving technology development Delivery of dyeing auxiliaries Dyeing quality control Formula digital energy saving Delivery of printing and dyeing auxiliaries