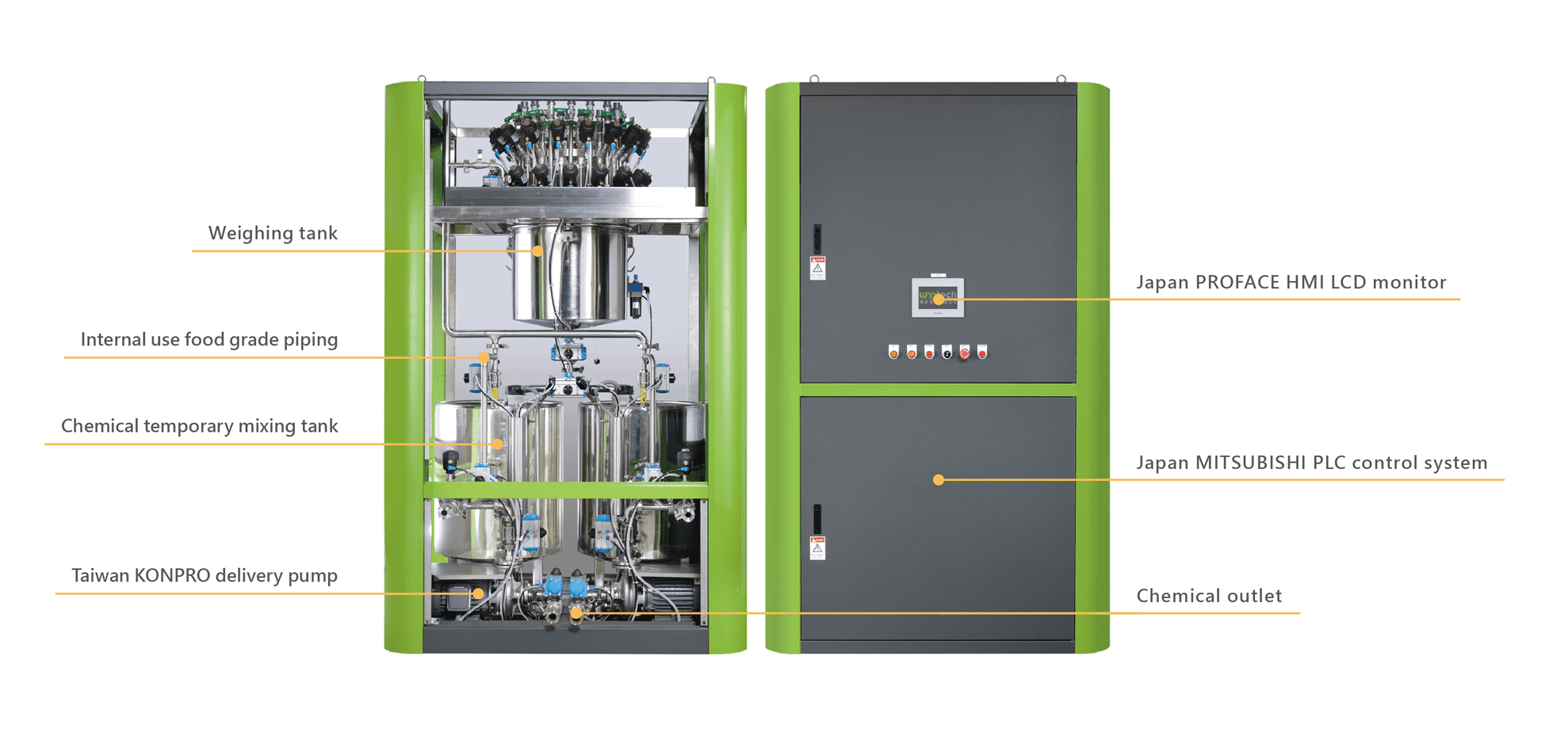

WF-2600-LC

Load Cell Type Dyeing Liquid Chemical Auto Weighing and DIstribution System

Feature

- The equipment adopts stainless steel mechanism.

- The standard equipment is equipped with one set of weighing barrels and two sets of mixed medicine preparation barrels.

- The system automatically controls the scale weight.

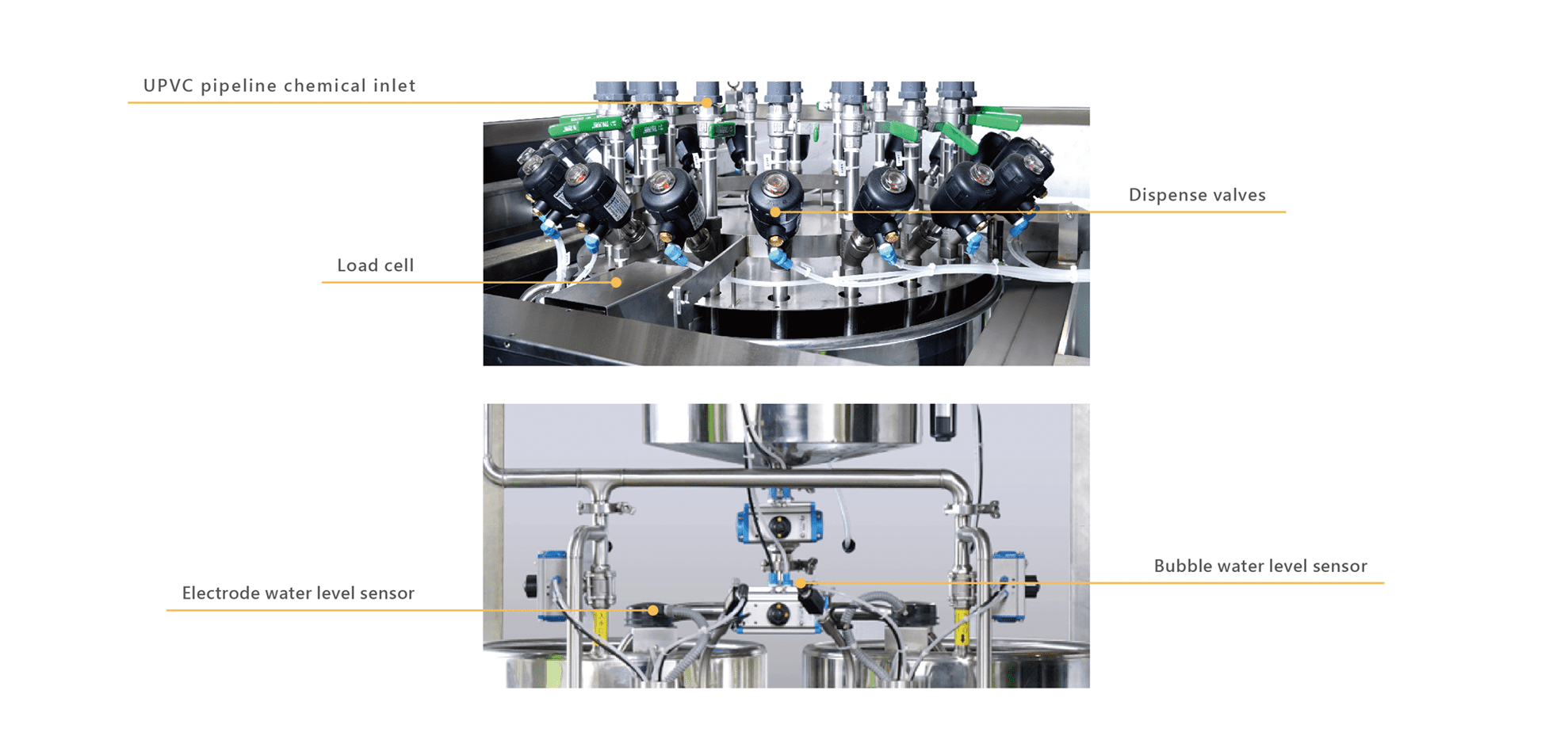

- A high-precision load cell is used.

- Adopt Japan Mitsubishi PLC control system.

- Two level controls are provided.

- Each auxiliary is equipped with an independent pipeline.

- Taiwan Zaixiang transfer pump is adopted.

- Provide two sets of blenders.

- Stainless steel three-way transfer valve with control element.

- The pipeline is automatically cleaned.

- A set of auxiliary pressure storage tanks is standard.

Benefit

Solve the problems of waste of auxiliaries and unstable dyeing quality caused by different hand quality. Measuring, conveying, and pipeline cleaning are completed at one time, reducing human error, improving work efficiency, querying and printing historical weighing information, standardizing weighing and conveying, improving the working environment of the auxiliary room, caring for the health of employees, and improving space utilization. , complete record of weighing information. At the same time, it is beneficial to environmental protection and improves product competitiveness.

Standardization of weighing and conveying Liquid Auxiliary Automatic Dispensing System Liquid transfer control cabinet Auxiliary automatic metering cabinet Guarantee the accuracy of measurement Professional customized designSpecification Table

| ITEM | Specification |

|---|---|

| Auxiliary Quantity | 1 - 32 Pics ( Customization ) |

| Auxiliary metering valve quantity | 1 - 32 Pics ( Customization ) |

| Number of high-precision load modules | 3 Pics |

| High-precision load module readable accuracy | ± 10 g |

| Measurement accuracy | ± 50 g |

| Weighing bucket | 1 / 50 L |

| Number of Mixed Temporary Buckets | 1-2 Pics ( Customization ) |

| Mixed bucket capacity | 100L-500L ( Customization ) |

| number of blenders | 1-2 Pics ( Customization ) |

| Auxiliary delivery pump quantity | 1-2 Pics ( Customization ) |

| Number of electric control boxes | 1 Pic |

| Number of operating boxes | 1 Pic |

| Number of man-machine interface | 1 Pic |

| Voltage | 380 V |

| Power Frequency | 50/60 Hz |

| Power Consumption | 2KW |

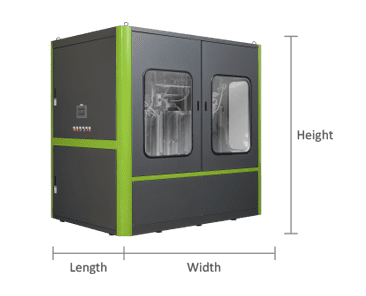

WF-2600-LC Dimensions

Length 170cm x Width 235cm (Depth) x Height 250cm

Specifications available upon request. Please feel free to contact us for more information.

Details