WF-2200

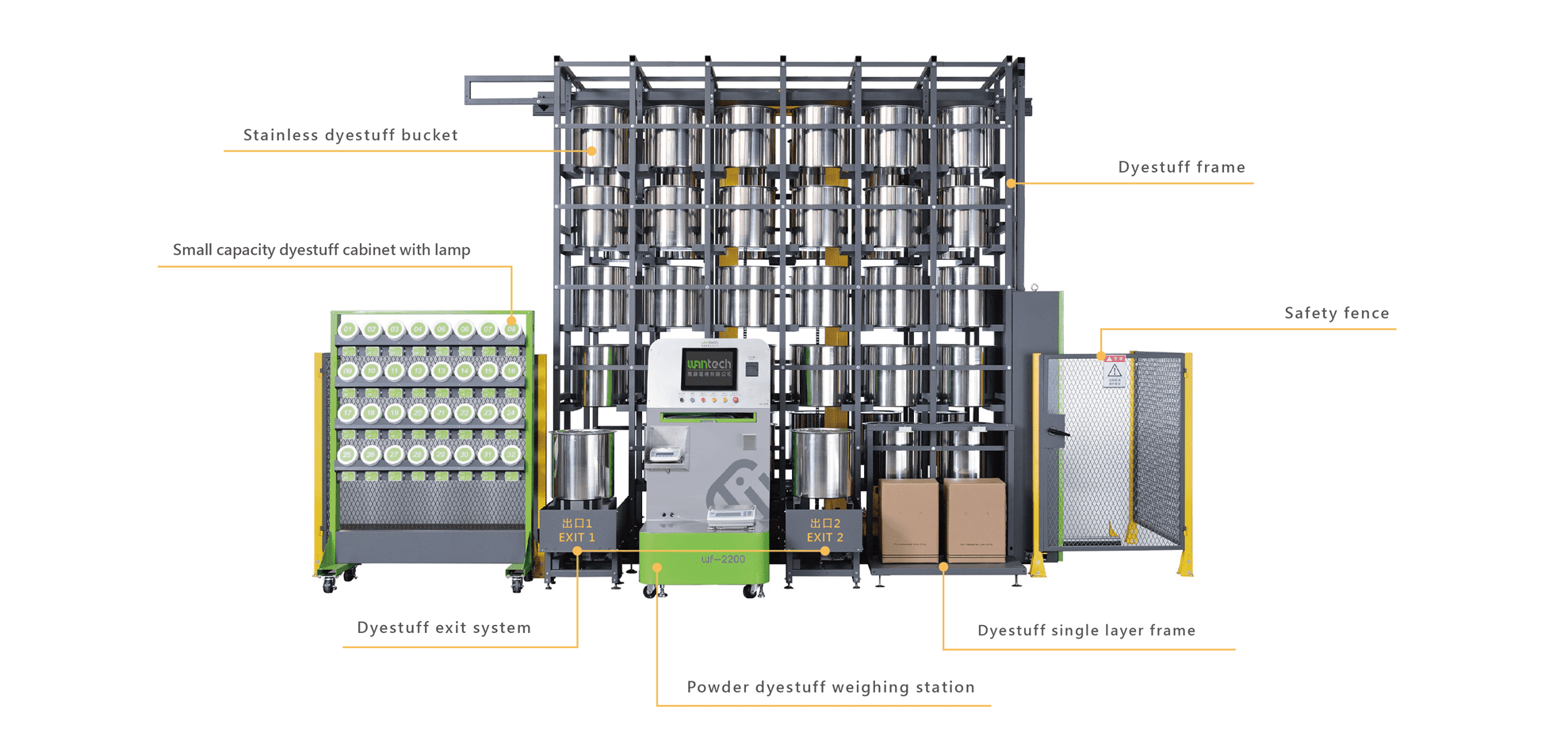

Ware House Type - Semi-Auto Powder Dyestuff Weighing System

Feature

- Provides two sets of material in/out systems.

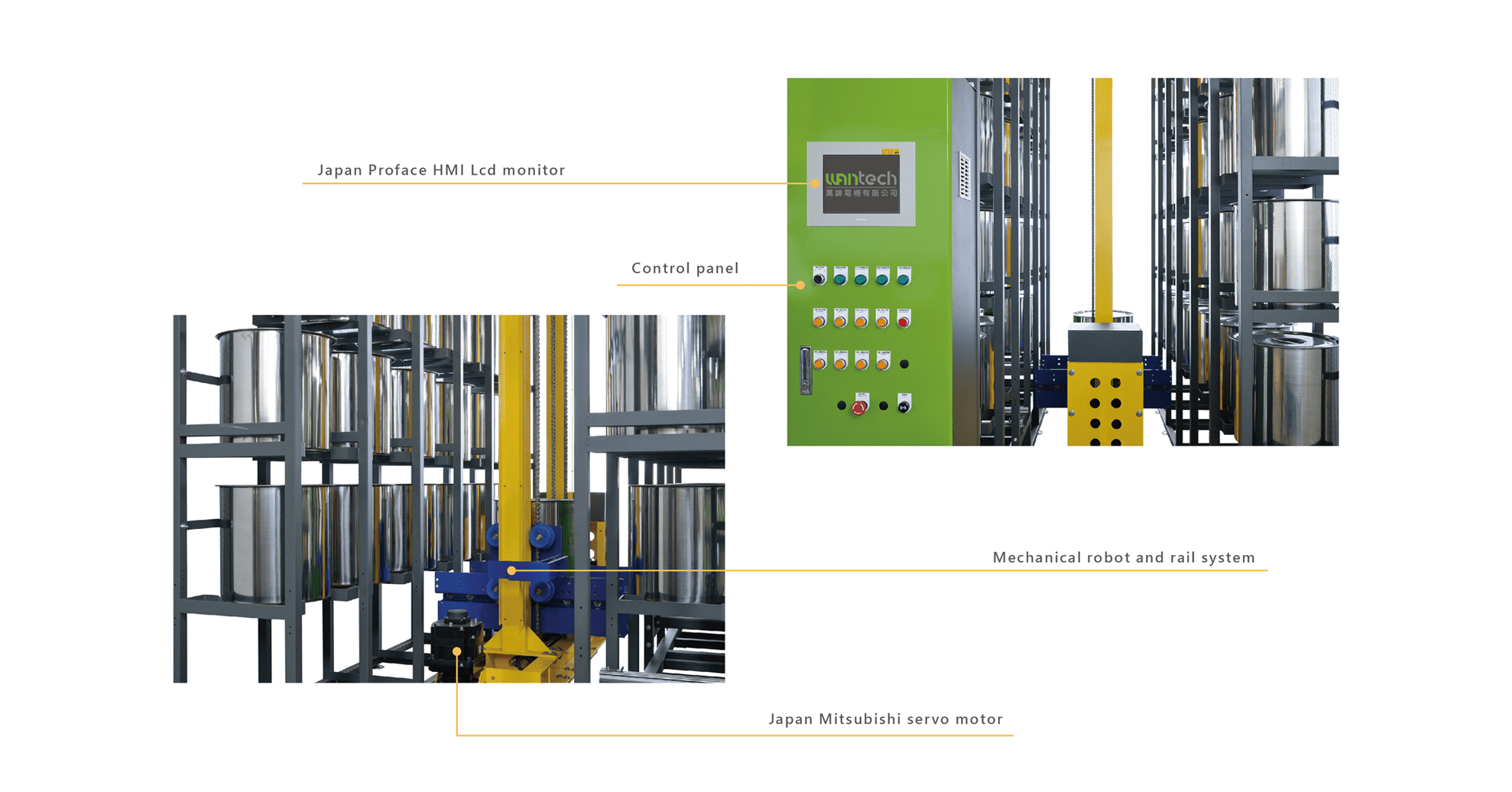

- Fully automatic robotic arm for dye delivery and retrieval.

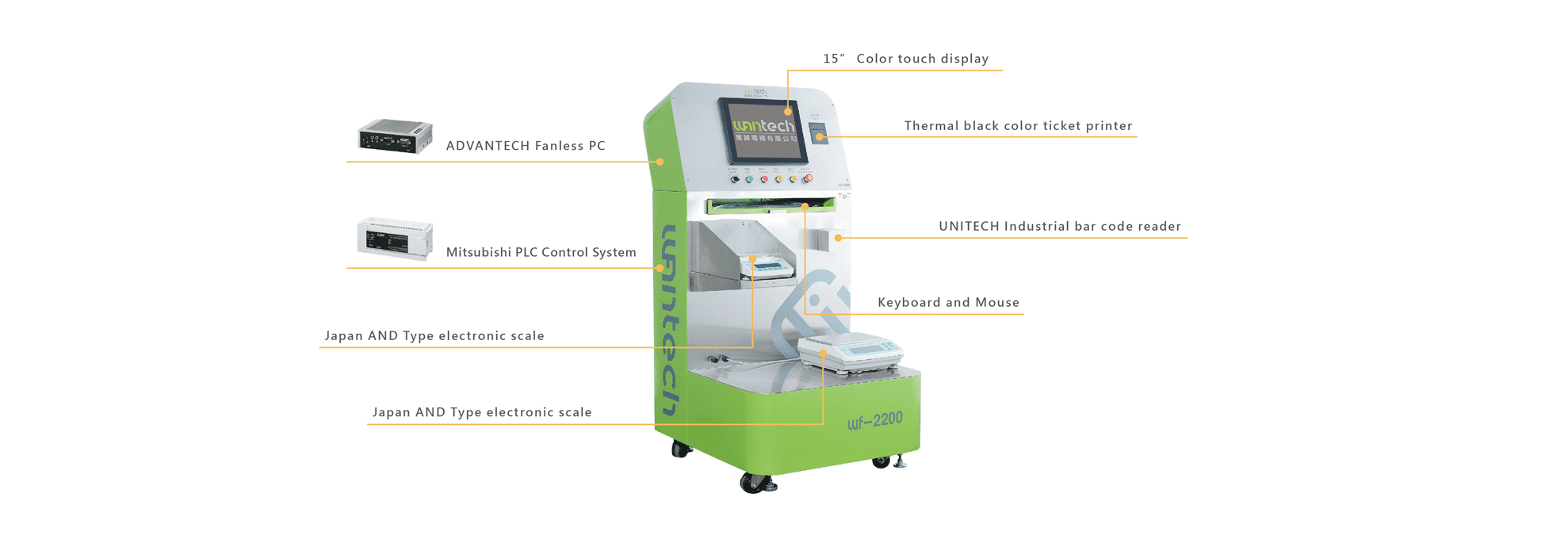

- Uses a Mitsubishi PLC control system from Japan.

- Uses a Mitsubishi servo motor control system from Japan.

- Equipped with an AND scale from Japan.

- Each dye is paired with a stainless steel bucket.

- Barcode reader for reading material requisition forms.

Benefit

The system software controls the weighing accuracy, records the weighing information completely, improves space utilization, reduces human errors, queries and prints historical weighing information, prevents dyes from getting wet, improves dyeing reproducibility, and improves the working environment of the weighing room.

Specification Table

| ITEM | Specification |

|---|---|

| Number of weighing hosts | 1 Pic |

| 3kg scale | 1 Pic |

| 3KG balance readable precision | ± 0.01g |

| 30KG scale | 1 Pic |

| 30KG balance readable accuracy | ± 0.1g |

| 15-inch touch screen quantity | 1 Pic |

| Number of Fanless Industrial Computers | 1 Pic |

| Number of barcode reading machines | 1 Pic |

| Thermal Induction Receipt Printer Quantity | 1 Pic |

| Dye Storage Rack quantity | 60-140 Pics ( Customization ) |

| Stainless Steel Dye Buckets quantity | 60-140 Pics ( Customization ) |

| Warehouse conveyor trolley and track system | 1 Pic |

| Reclaiming and exporting system | 2 Pics |

| Number of electric control boxes | 1 Pic |

| Number of man-machine interface | 1 Pic |

| Voltage | 220 V |

| p\Power frequency | 50/60 Hz |

| Power consumption | 8KW |

WF-2200 Dimensions

Length 680cm x Width 360cm(Depth) x Height 290cm

Specifications available upon request. Please feel free to contact us for more information.

Details